Because of their unmatched combination of soundproofing, insulation, and structural efficiency, lightweight, environmentally friendly AAC blocks are quickly becoming popular in contemporary architecture. These cutting-edge building blocks are made by top AAC block producers in Hyderabad and provide affordable, sustainable solutions perfect for commercial, industrial, and residential applications looking to improve performance and environmental responsibility. This article examines how the use of AAC blocks changes designs by offering significant benefits in terms of acoustic comfort, thermal control, and structural strength.

Autoclaved aerated concrete blocks, or AAC blocks, are distinguished by its porous cellular structure that is packed with trapped air pockets. AAC blocks are around three times lighter than conventional bricks because to its special microstructure, which drastically lowers density. This makes handling easier, construction quicker, and less structural load-bearing. Because of their uniform size and smooth surface, they guarantee accurate installations with less mortar and reduced material waste.

1. Construction Ease and Structural Efficiency

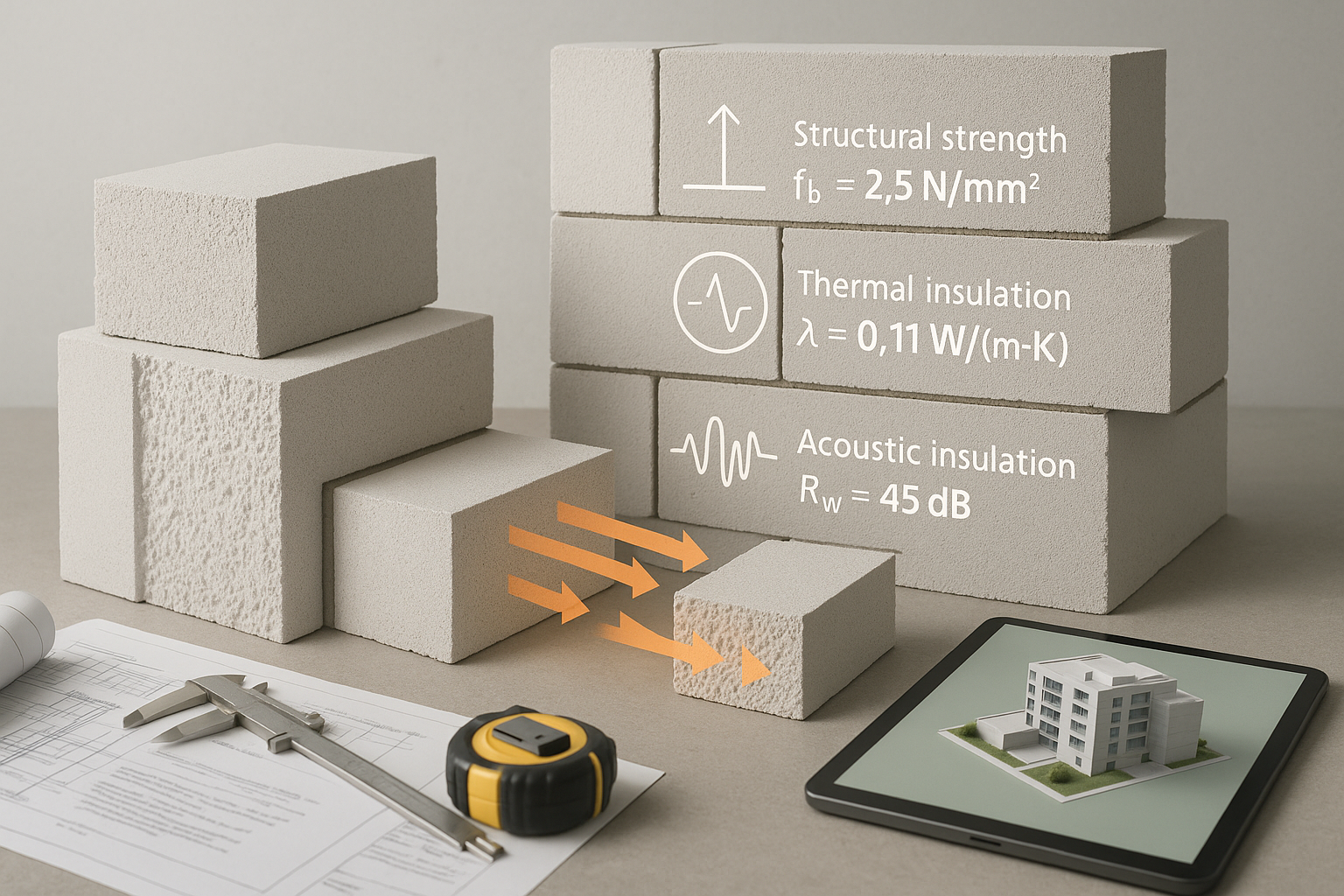

Because AAC blocks are lightweight, they lessen dead loads on structural frames and foundations, enabling architects to create smaller footings and slimmer columns. This preserves strength while reducing total construction costs. Mid-rise buildings’ load-bearing walls can benefit from the moderate compressive strength of AAC blocks, which also allow for simple alterations such cutting for plumbing or electrical conduits without sacrificing structural integrity.

Fast assembly and less work are made possible by AAC block manufacturers in Hyderabad, who guarantee dimensional precision and consistency. The blocks are a great option for sustainable modern buildings because of their thermal stability and resistance to mold and pests, which contribute to long-lasting, low-maintenance construction.

2. Energy Efficiency with Superior Thermal Insulation

Outstanding thermal insulation qualities are conferred by the unique cellular structure of lightweight, environmentally friendly AAC blocks. By inhibiting heat movement and preserving controlled indoor temperatures, their air pockets serve as organic barriers. Up to 30% less HVAC energy is used in buildings built with AAC blocks because they stay warmer throughout the cooler months and are noticeably cooler during India’s scorching summers.

This thermal efficiency is ideal for India’s need for energy conservation and green building certifications. Using AAC blocks lowers the building’s lifetime carbon emissions and operating expenses by reducing the need for artificial heating and cooling.

3. Improved Comfortable Acoustic Performance

AAC blocks are excellent at providing sound insulation in addition to thermal benefits. Because of their porous structure, sound waves are absorbed and noise from outside sources like traffic and industrial activity is not transmitted between rooms. AAC blocks can create more private and quiet interior spaces with a sound transmission class (STC) rating of about 44.

This feature is particularly useful in multi-family housing complexes and densely populated urban locations where noise pollution affects tenant well-being. Architects who select AAC blocks benefit from a wide range of design options that naturally improve indoor acoustics.

4. Environmental Impact and Sustainability

AAC blocks are regarded as environmentally benign for a number of reasons. Compared to conventional clay bricks or concrete blocks, their manufacturing process uses less energy and makes use of industrial waste materials like fly ash. Their lightweight design also lowers pollution and fuel consumption during transportation.

Manufacturers of AAC blocks in Hyderabad frequently highlight how recyclable and waste-free their goods are. Projects that use AAC blocks support India’s sustainable development objectives and lessen resource depletion and environmental impact on the country’s growing construction industry.

5. Safety Compliance and Fire Resistance

In contemporary building, safety is of utmost importance. Depending on the thickness of the wall, AAC blocks may withstand temperatures of above 1,200°C and offer up to 4 hours of fire protection. This feature outperforms many traditional construction materials, providing improved occupant safety and the regulatory compliance required for both residential and commercial structures.

Because AAC blocks are long-lasting and non-toxic, they help provide safer emergency responses and insurance benefits, which supports their incorporation into institutional and high-rise projects.

Using Eco-Friendly, Lightweight AAC Blocks to Advance Modern Construction

Lightweight eco friendly AAC blocks provide builders and architects a special, well-rounded solution for today’s construction problems. Building design paradigms in India are redefined by AAC blocks produced by reputable AAC block maker Hyderabad, which combine structural efficiency, thermal and acoustic performance, sustainability, and fire safety.

Utilizing these adaptable blocks promotes environmental stewardship, occupant comfort, and energy conservation—all of which are essential tenets of sustainable urban development in the future.