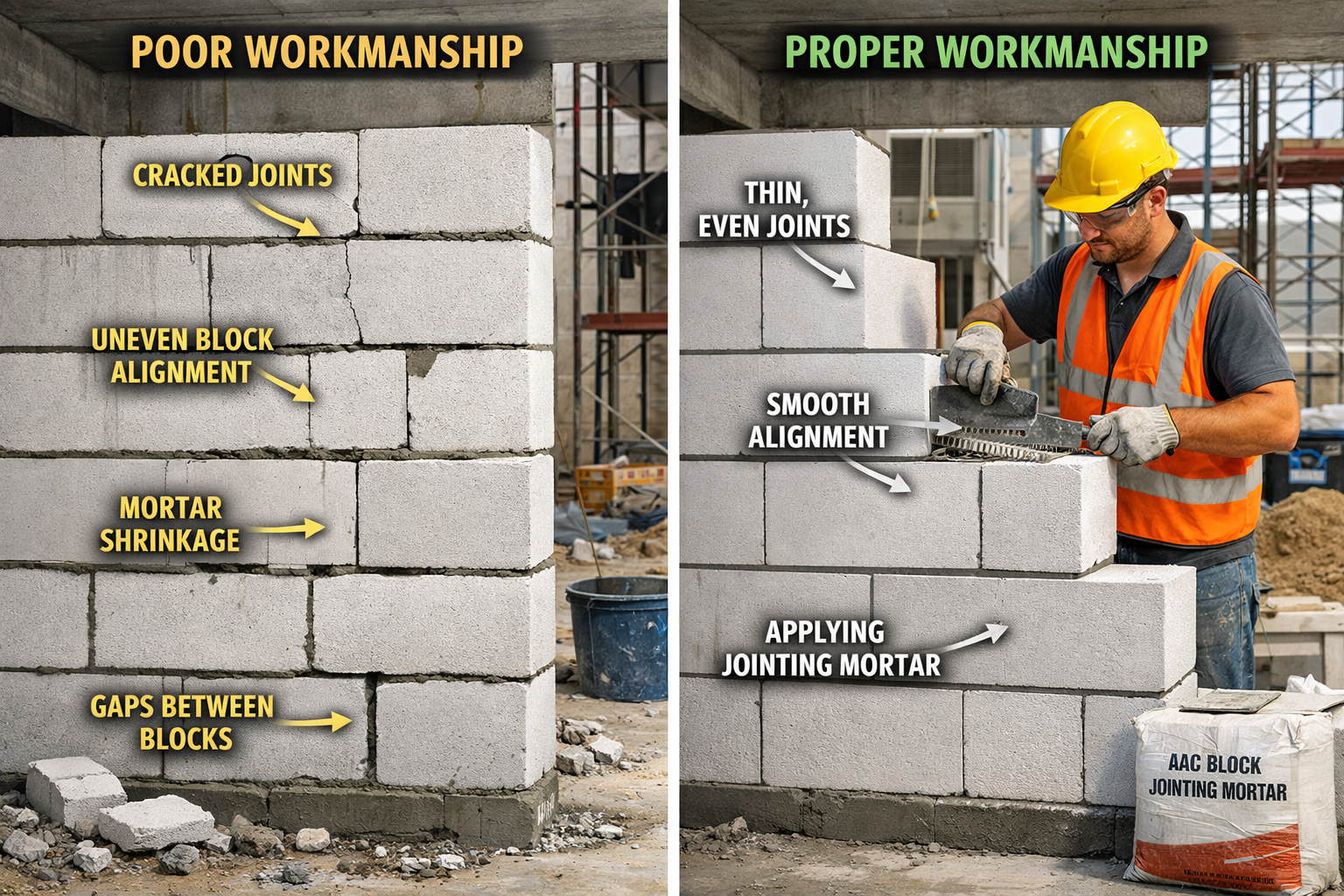

Because of their speed of construction, thermal insulation, and light weight, AAC blocks are widely used. Nevertheless, many AAC masonry walls experience alignment problems, debonding, or cracks soon after construction, despite their benefits. Most of the time, poor jointing techniques are the cause of the failure rather than the blocks themselves.

Using traditional cement-sand mortar rather than specialized solutions is one of the most frequent errors made on the job site. Preventing structural and finishing flaws that jeopardize long-term performance requires careful application of AAC block jointing mortar and selection of the appropriate ready-mix mortar.

1. Breaking Because of Differential Motion

The behaviour of AAC blocks differs from that of conventional clay bricks. They exhibit distinct thermal expansion properties and greater dimensional accuracy. Stress accumulates between the block and the joint when thick conventional mortar joints are used.

The purpose of specialized AAC block jointing mortar is a thin-bed application, usually ranging from 2 to 3 mm. This considerably lowers the chance of shrinkage and thermal cracks in masonry walls by minimizing differential movement and uniformly distributing stress.

2. Debonding Due to Weak Bond Strength

Inadequate block bonding is another common site failure. The adhesive strength needed for smooth AAC block surfaces is frequently lacking in traditional mortars, which causes separation under load or vibration.

Polymer additives that improve adhesion are found in premium ready-mix mortar for AAC blocks. As a result, blocks form a stronger chemical and mechanical bond, guaranteeing wall integrity even in the event of seismic activity or structural movement.

3. Inequitable Classes and Alignment Problems

The precision manufacturing of AAC blocks is offset by thick mortar joints. In order to fix flaws, uneven mortar layers result in misaligned courses, wavy walls, and thicker plaster.

Block alignment is maintained with uniform, thin joints made possible by the use of AAC block jointing mortar. This leads to faster construction cycles with better visual quality, straighter walls, and less material used in finishing stages.

4. Moisture Damage and Excessive Water Absorption

Water absorption in masonry can be increased by using the wrong mortar. Because conventional cement mortars frequently have higher porosity, moisture can enter the wall through the joints.

For AAC blocks, specialized ready-mix mortar is designed to regulate permeability and water retention. By doing this, moisture intrusion is decreased, damp patches are avoided, and interior finishes are shielded from long-term harm brought on by water migration.

5. A Rise in Finishing Failures and Plaster Cracking

Rather than the plaster itself, masonry joints are the source of many plaster cracks. Over time, stress points created by thick joints and incompatible mortar compositions telegraph through layers of plaster.

Plastering is made on a stable and consistent surface when the proper AAC block jointing mortar is used. This increases plaster adherence, decreases the likelihood of cracks, and prolongs the life of finished finishes, particularly for large wall spans.

The Foundation of AAC Masonry is the Proper Mortar

The majority of masonry failures in AAC blocks can be avoided. One common root cause of cracks, debonding, alignment problems, and moisture issues is improper choice or application of jointing mortar.

Contractors can guarantee stronger walls, better finishes, and longer-lasting performance by using a premium ready-mix mortar for AAC blocks and adhering to best practices with AAC block jointing mortar. The proper mortar is a structural requirement in AAC construction, not an add-on.